| Sign In | Join Free | My xpandrally.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xpandrally.com |

|

Brand Name : HEROLASER

Model Number : ML-MF-200l-LC

Certification : CE/ISO9001/FDA

Place of Origin : CHINA

MOQ : 1 Set

Price : $

Payment Terms : T/T, L/C, D/A, D/P, Western Union, MoneyGram,Paypal

Supply Ability : 100 Sets Per Month

Delivery Time : 7-10 Work days

Packaging Details : Plywood Box

Model : ML-MF-200l-LC

Laser Power : 200W

Laser Source Type : IPG Fiber Laser Source

Laser Wavelength : 1064 nm

Cooling Method : Water cooling

Cooling Water : Deionized water

Water Temperature : 18-22 ℃

Maximum Power : 200 W

Scan Width : 10-60mm

Auxiliary Gas : Compressed air/Nitrogen

Air Pressure : 0.5-0.8 MPa

Working Condition : 5-40 ℃

![]()

Fiber Laser Rust Removal Machine 200W Removal Resin Noncontact Cleaning

laser cleaning machine can remove resin,oil,stain,contaminant,rust,coating,plating,paint etc,.Laser cleaning is a new technology based on the interaction effect between laser and matter.Unlike traditional mechanical cleaning,chemical cleaning and ultrasonic cleaning it does not require any CFC that destroys the ozone layer Organic solvents,no pollution,no noise,harmless to the human body and the environment,it is a "green"cleaning technology.

![]()

| Description of high efficiency laser cleaning machine | ||

| Model | ML-MF-200l-LC | |

| Laser power | 200W | |

| Laser source type | IPG fiber laser source | |

| Laser wavelength | 1064 nm | |

| Cooling method | Water cooling | |

| Cooling water | Deionized water | |

| Water temperature | 18-22 ℃ | |

| Cabinet size | 1420mm*850mm*1370mm (L*W*H) | |

| Total weight(with water tank) | 225kg | |

| Maximum power | 2000W | |

| Focal depth | 10mm | |

| Scan width | 10-60 mm | |

| Auxiliary gas | Compressed air/Nitrogen | |

| Air pressure | 0.5-0.8 MPa | |

| Optional accessory | Handheld / Manipulator | |

| Working condition | 5-40 ℃ | |

![]()

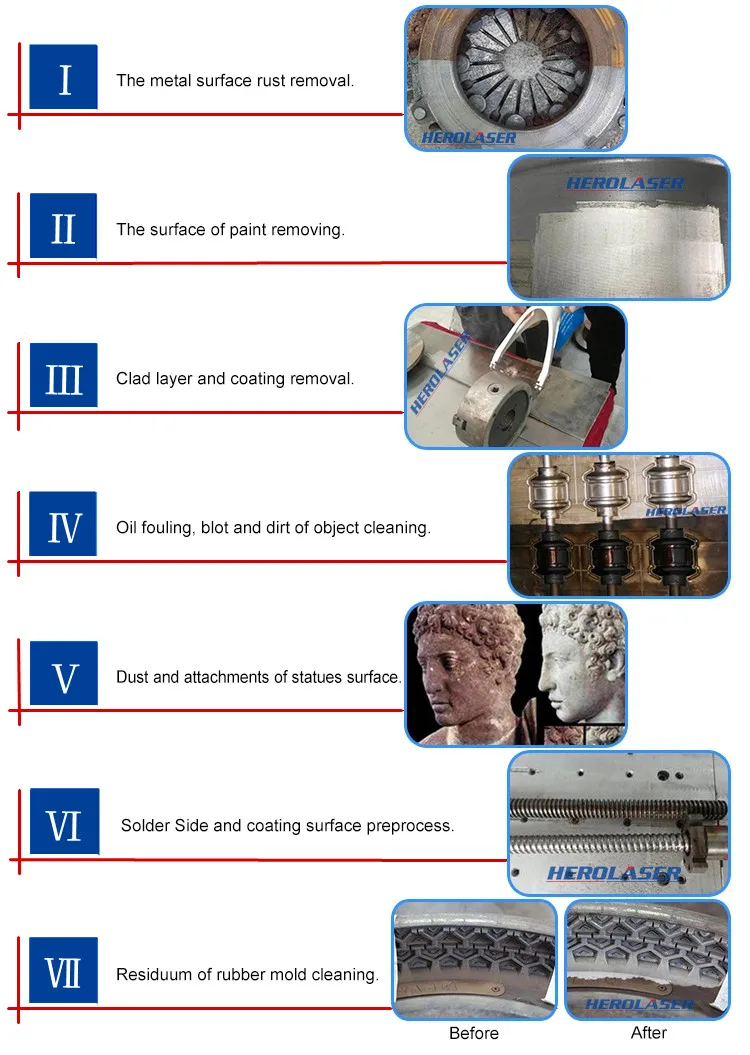

| Application | |||

| Rust Removal | Oxide Removal | Molding Cleaning | Surface Preparation |

| Paint Removal | Surface Cleaning | Stain Removal | Surface Roughening |

| Tool Cleaning | Historic Restoration | Selective Paint Removal | Precise Cleaning |

![]()

![]()

![]()

Five categories in conventional cleaning process:

(1)

Mechanical cleaning process, which cleans the surface by physical smearing, scrubbing, and

brushing. However this ineffective cleaning method can easily damages the surface of the

substrate.

(2)

Chemical etching process, which removes the surface contaminant by spraying or vibrating

through organic cleaning solvent. However dirty areas with multiple material compositions

are difficult to remove and need multiple times of procedures through this environmental

unfriendly cleaning process.

(3)

Sand-blasting cleaning process can cause serve dust pollutions during the process, which

can harm operator’s personal health.

(4)

Ultrasonic cleaning process is based on the ultrasonic vibration phenomenon that can

effectively clean the surface of materials. However materials with large geometry size or

complex shape structure are unable to be cleaned in this method, also the surface can be

easily oxidised after ultrasonic cleaning process.

(5)

Dry-ice cleaning process is a high-running cost cleaning process. It has some drawbacks –

storage of dry-ice and collection of the contaminant after the process.

|

|

HEROLASER 200W Laser Cleaning Machine , Handheld Laser Rust Remover Images |